How we make bath whisks

We are proud of the quality of our whisks!

Here you will find a complete description of our production process and can learn how to make a bath whisk from environmentally friendly forest resources, that will bring pleasure in the bathhouse.

Step 1

Cutting branches

Twigs are cut from young trees with mature foliage away from industrial facilities and are gathered in bunches.

Step 2

Air-drying material

The collected bunches are tied in 2 pieces and hung up on stretched ropes and poles in a dry, dark, and well-ventilated room. The air-drying process is monitored daily.

Step 3

Tying up a whisk

Skilled whisk makers assemble whisks from dried twigs, taking into account all the necessary standards. At the request of a client, a medley of meadow herbs can be added to the whisk.

Step 4

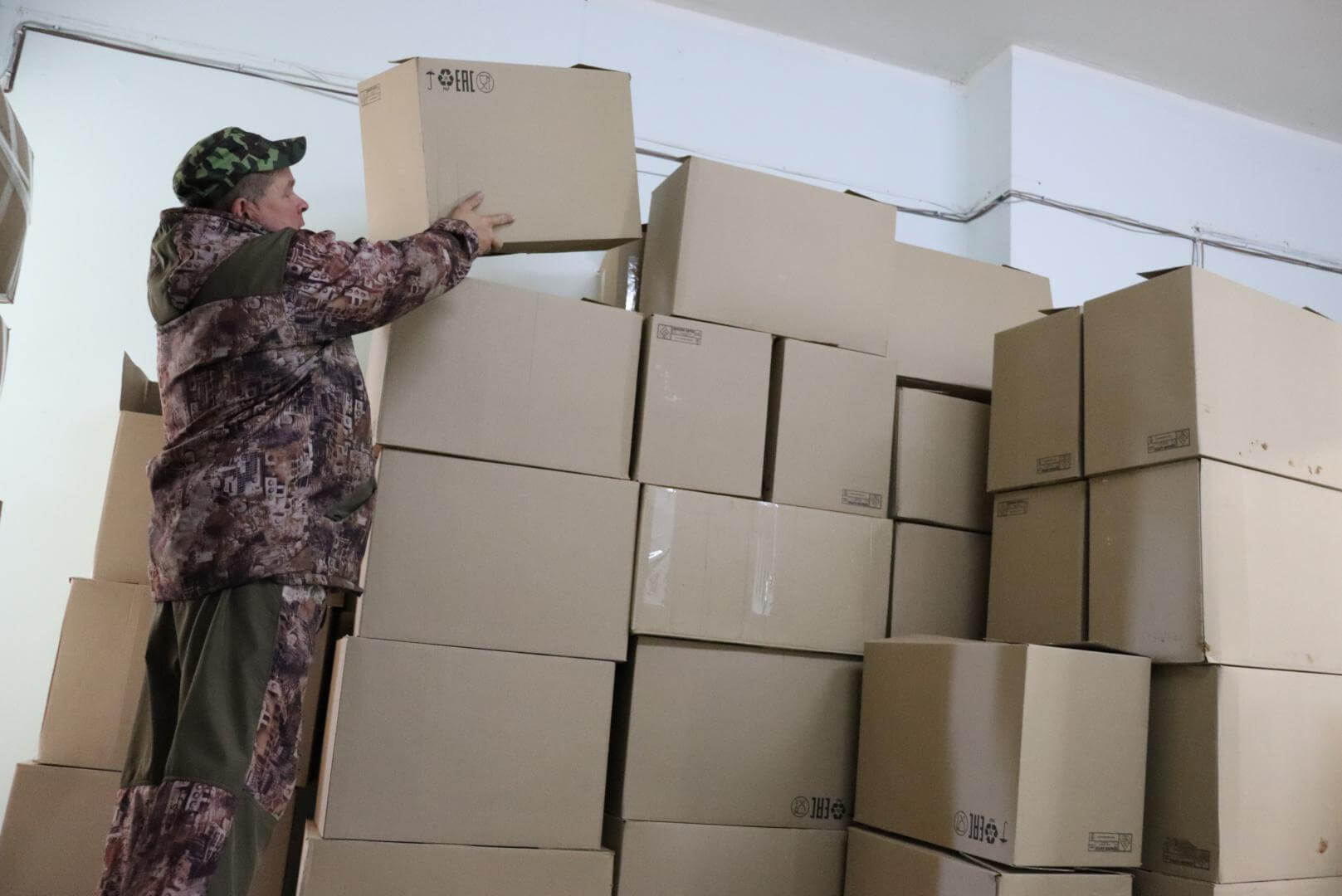

Whisks’ storage

Completed whisks are put in cardboard boxes for pressing and storage. The boxes are stored on wooden pallets in a dry and dark room.

«That's all! Now we just have to pack and ship ready-made whisks according to your order, and you can enjoy taking a steam-bath, remembering us with a kind word!»

«Many make bath whisks — we handcraft quality ones!»